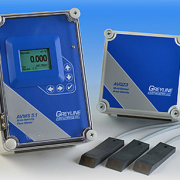

Greyline PSL 5.0 Pump Station Level Controller

Pump Station Level Controller – Vancouver BC

At Southwell Corp, we have been selling and supporting Greyline flow meters in Vancouver and throughout BC for over 15 years. We recommend the Greyline PSL 5.0 Pump Station Level Controller for pump stations, wet wells and tank level control.

PSL 5.0 Pump Station Level Controller

- 6 Control Relays

- Programmable Pump Alternation

- Relay Run Time Reports

- Redundant Sensor Input

- Isolated 4-20mA Output

- Large Backlit Display

Call 1.844.599.0260 to request a quote or email sales@SouthwellCorp.com

Pump Station Level Control, Monitoring and Reporting

Designed for pump stations, wet wells and tank level control the new Greyline PSL 5.0 Pump Station Level Controller has six independently programmable control relays for pump or valve control, level alarms, autodialers, temperature or fault alarms.

No contact, No maintenance

Mount the non-contacting, ultrasonic sensor in the tank or wet well and install the watertight electronics in the control room or any location within 500 ft / 150 m. Use the simple menu system and built-in keypad to set up measurement range, relay set points and pump alternation sequence. A relay/pump run time report is updated and stored automatically for viewing on the instrument’s backlit LCD display.

Dual-Technology Sensor Feature – Redundant Level Sensing

Connect a submersible pressure sensor or other 4-20mA level transmitter to the PSL 5.0 for fail-safe hybrid sensing. The PSL 5.0 will auto-calibrate the redundant sensor and if signal is lost to the ultrasonic sensor, the redundant sensor will seamlessly take over monitoring until signal resumes from the ultrasonic. The redundant sensor is continuously monitored to ensure availability during primary sensor failure.

Easy to Install with Non-Contacting Sensor

The PSL 5.0 Pump Station Level Controller is designed for Pump Station and Tank Level Control applications. Mount the non-contacting ultrasonic sensor above the well or at the top of a tank. Use the built-in keypad to calibrate measurement span, relay set-points, pump alternation sequence and level alarms. Assign the six built-in control relays for ON/OFF pump control, Hi or Lo level alarms, autodialer activation, air temperature alarm or sensor echo loss alarm. Connect the isolated 4-20mA output to your SCADA system, PLC’s or recorders.

Redundant Sensor Level Control

The PSL 5.0 sets a new level of reliability. It operates with an ultrasonic level transducer as its primary sensor but also accepts connections from 4-20mA level sensors for redundancy. If the ultrasonic transducer loses signal from foam on the water surface for example, the redundant sensor will take over reading instantly. As soon as the ultrasonic sensor receives new echoes, it will resume function as the primary sensor.

An animated icon on the PSL 5.0 digital display indicates that the ultrasonic sensor is active. The icon indicates if the system automatically switches to the redundant sensor.

Calibration of the Redundant Sensor is Totally Automatic

You can use hydrostatic pressure sensors, radar, or any 4-20mA transmitter for redundant level sensing. The PSL 5.0 automatically scales and calibrates the redundant sensor during each pump cycle. Once the PSL has operated through at least one pump cycle, the redundant sensor will be calibrated and ready to function.

Ideal for Water, Wastewater and Process Automation

Use the PSL 5.0 Pump Station Level Controller for pump or level control and for

automatic pump alternation/sequencing. It is designed for the harsh operating conditions in wet well or tank level control applications. The non-contacting ultrasonic sensor mounts at the top of a wet well or tank, and you can connect a redundant 4-20mA level sensor for added reliability in challenging pump station applications.

Relay Run Time Reporting System

View the PSL 5.0 relay run time report directly on the backlit digital display. You can identify “lazy” pumps pump failures occur and plan pump maintenance to reduce call-outs and down-time. If a redundant level sensor is connected its operation time is also indicated.

Greyline Flow Meters are available in BC through Southwell Corp. We ship to Vancouver, Victoria, Burnaby, New Westminster, Surrey, Abbotsford, Kelowna, Kamloops, Vancouver Island, Prince George and every other town in BC.

Call 1.844.599.0260 to request a quote or email sales@SouthwellCorp.com

Applications for Greyline Flow Meter Products

Greyline Flow Products are known across many industries as reliable sources of data for your flow systems.

Discuss the specific needs of your project with one of Fiberman’s Greyline flow meter experts. We will ensure that the model you select will have the specifications required for safety and optimum performance. You will also benefit from our industry-leading quick quote turnaround and fast delivery across Canada and the US.

For all Greyline Flow Meter inquiries, please call 1.844.599.0260 or email sales@fiberman.ca or Request a Quote.

1.844.599.0260

Our Flow Meter experts are ready to help.

Bulk and Wholesale Discounts Available on Large Orders

Fast Delivery across Canada and USA via our Superior Logistics Network

Fast Delivery across Canada and USA via our Superior Logistics Network

We can ship Greyline Flow Meters from a distribution center close to you:

Fiberman’s headquarters in Western Canada stocks many Greyline Flow Meter models, ready to ship across British Columbia, Alberta and all provinces in Canada. We have daily shipments from Vancouver to destinations including Edmonton, Calgary and Fort McMurray. For our US customers, we ship from distribution centers in: Pittsburgh, PA; Houston, TX; Knoxville, TN; Rochester, MN; Salt Lake City, Utah; and Orlando, FL.

Fiberman’s pricing and service experts are standing by to help to find the best product for your project. With many varieties in stock and expedited shipping, we can supply your project with flow meters at the best possible price with fast delivery.

![]()

Fiberglass and Radio Frequency Transparency

In today’s connected world, we depend on cellular telephone signals, Wi-Fi networks and over the air radio and television signals. Wi-Fi and Bluetooth connectivity are essential to on-site work environments. Steel structures significantly disrupt these signals. Fiberglass Grating is an essential part of building structures that are “electronically transparent” and do not interfere with radio frequency transmissions.